SCADA

SCADA stands for Supervisory Control and Data Acquisition.

This is a full-scale monitoring and control system.

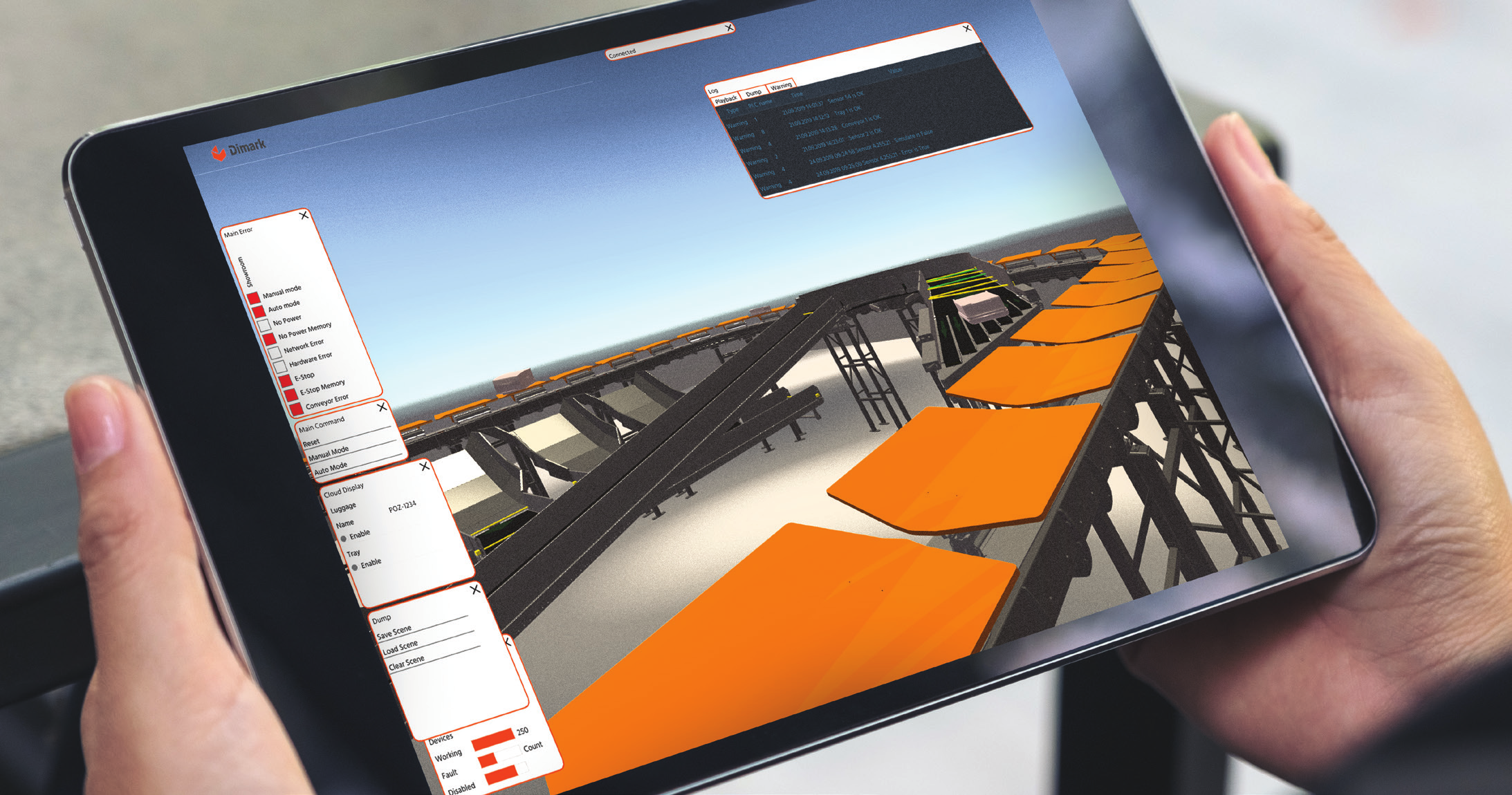

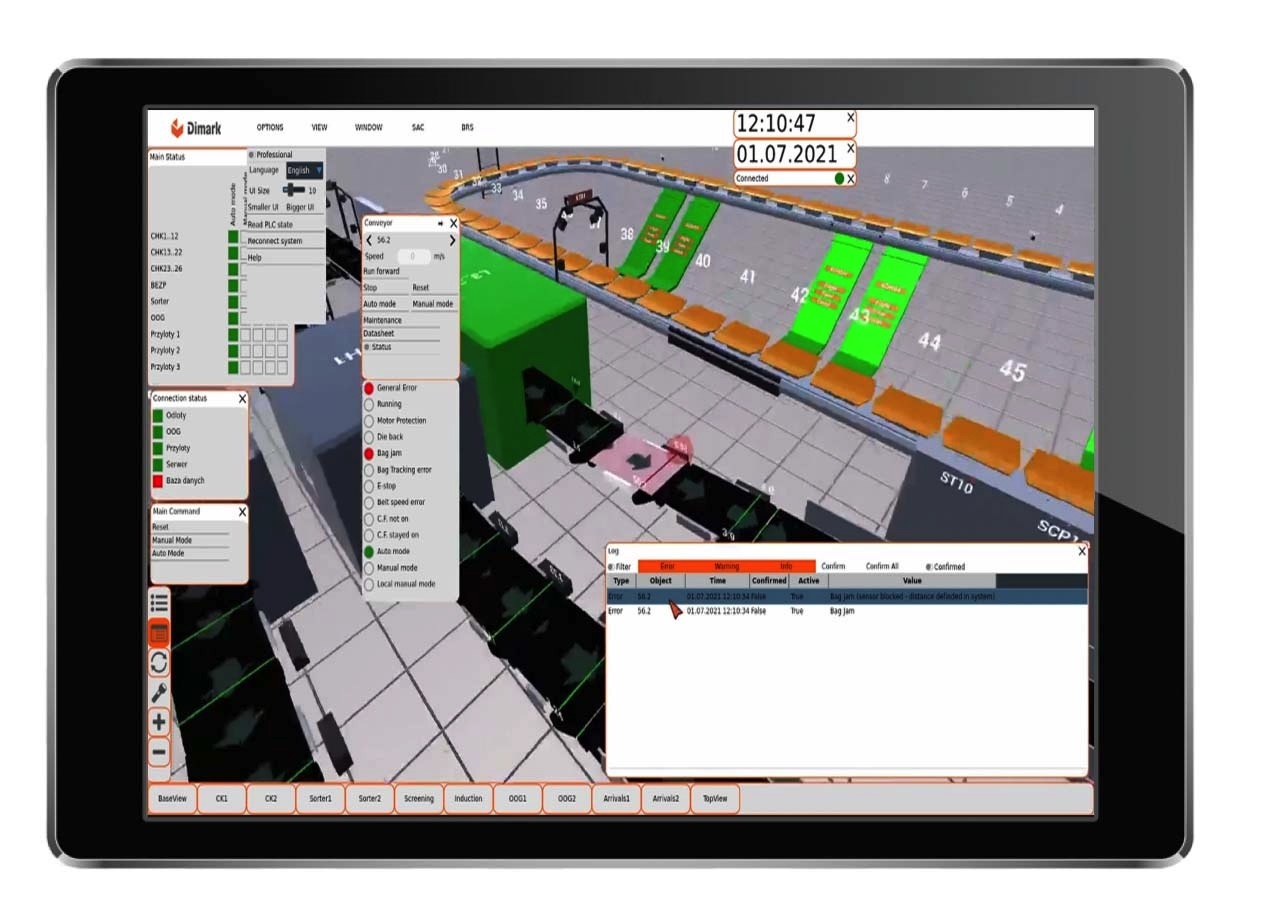

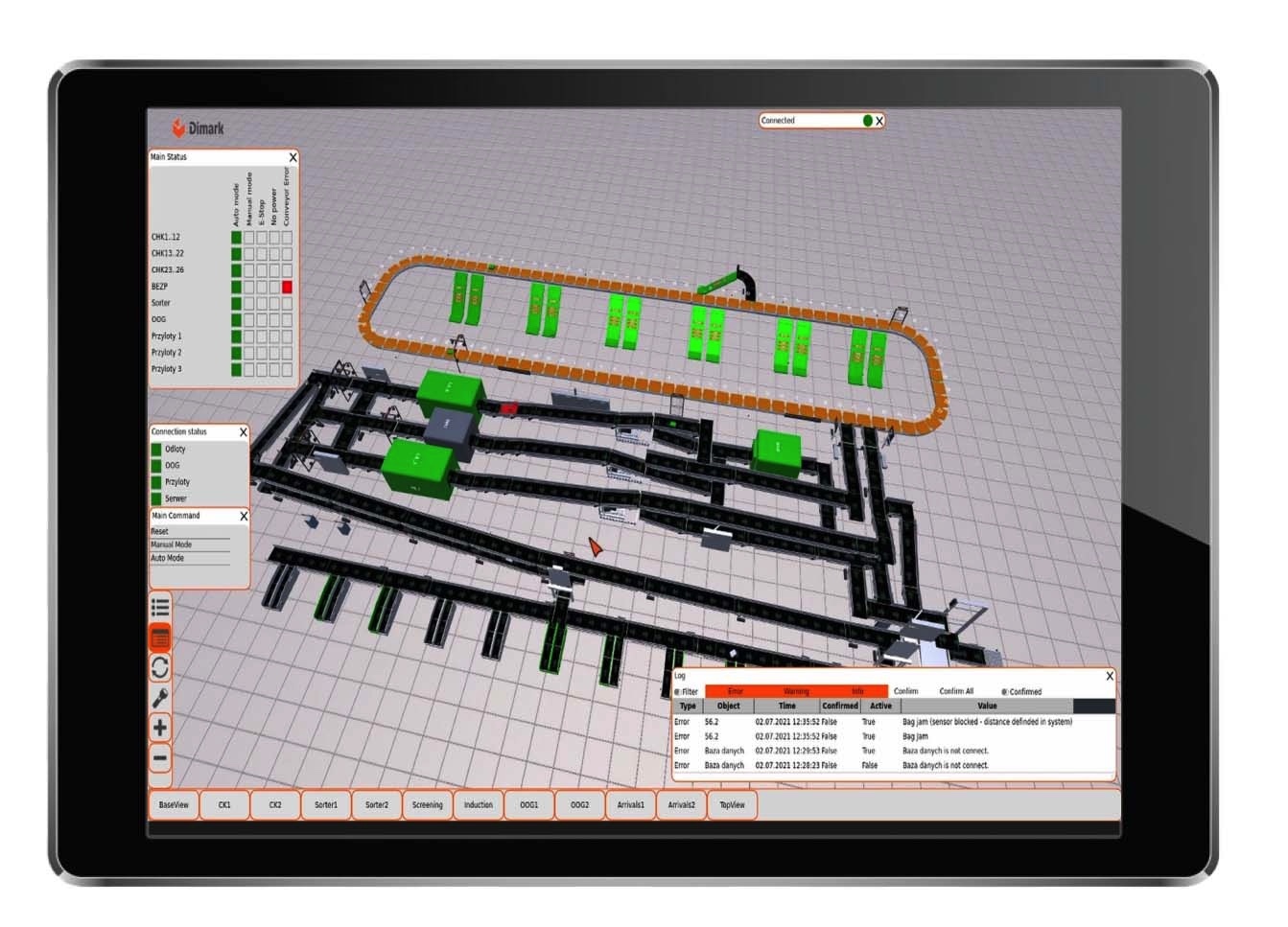

An absolutely revolutionary tool which thanks to advanced techniques makes it possible to take the operator’s work to a whole new level.The platform enables clear, precise and fast presentation of all information about the BHS system and luggage. Integration with PLC, SAC,BRS, CCTV and SCADA provides access to all

necessary information about every element of the facility, including baggage and flights data.The possibility of using multi-monitor workstations combined in the walls of monitors thanks to realistic 3D visualization significantly affects the perception of the entire installation.

- simulation of physical parameters of baggage and transporters

- current and historical analysis of the baggage stream flow

- interactive and intuitive user interface

- realistic reflection of reality

- improving the system perception in operational planning

- prediction of system behaviour

- easy access to project and service documentation

- virtual and augmented reality

- service planning

- reduction of service and maintenance time to a minimum

- optimalization of operational, investment and business activities

01

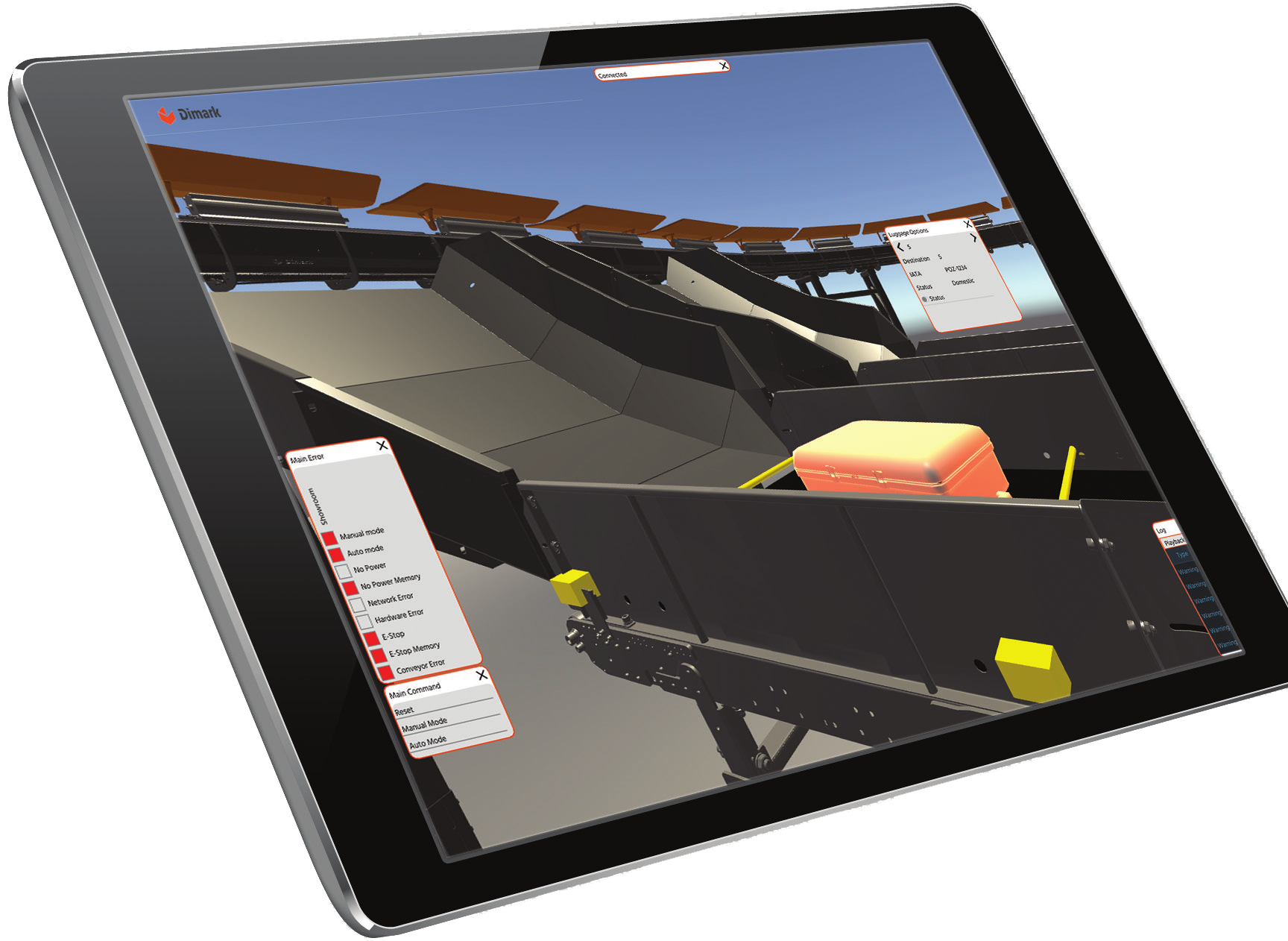

Visualization

Excellent model mapping allows for precise diagnostics using augmented reality technology. The software also allows working on tablets for quick access to data on BHS components. Remote access provides support for competence centers.The software, using full tracking and control of the system, presents the current flow of baggage along with the status of the entire BHS system. Thanks to data backup and user-friendly interface it is possible to quickly analyse historical events. Recording alarms, warnings and events together with integration of CCTV allows for quick and precise actions based on in-depth diagnostics and system perception.

02

Simulations and Predictions

An innovative solution developed by Dimark IT, taking into account physical properties such as shape, weight, centre of gravity, friction, etc., allows for an accurate representation of reality. Thanks to this it is possible to simulate and predict the behaviour of the entire installation in extreme situations, find the bottleneck of the system and choose the most efficient way to use the facility or propose modifications.

03

Management

User-friendly, advanced diagnosticand control tools allow for quick access to all necessary information from a single location. Interactive visualization and integration with design and maintenance documentation allows for planning and verification of the service. Information support about the history of system operation, extensive diagnostics along with reports and statistics allow for precise planning of BHS service. Quick and easy access to project and service documentation and the ability to easily operate the system reduces to a minimum the time needed to restore the system to work in the event of any failure or maintenance work.