automation control system

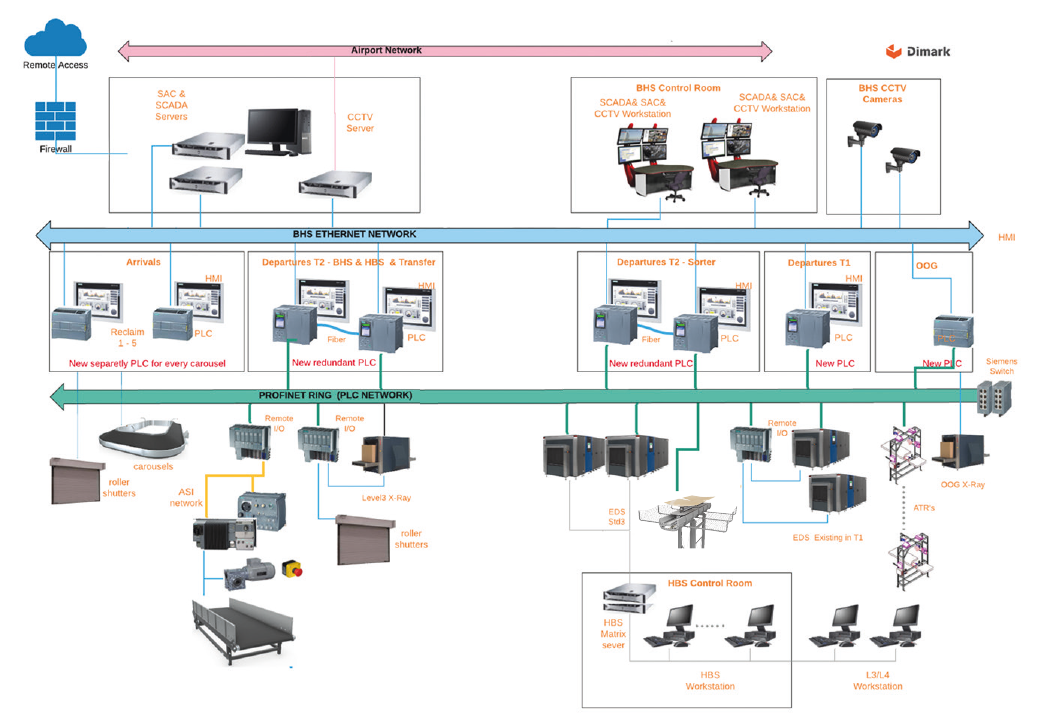

The Dimark automation control system ACS is a group of automation subsystems that manage and control the entire process of controlling the transport process and identification system.

ACS consists (LLC) Low Level Control, Identification, Measuring and Communication subsystems. These systems are based on modern components from reputable companies, such as SIEMENS, EATON, Peperl & Fush, DATALOGIC, SICK, RITTAL, PhoenixContact, DELL, etc. Many years of close cooperation with these companies and our own research and development department have resulted in many excellent solutions ensuring fast, failure-free, precise and resistant to difficult working conditions. The implemented Industry 4.0 solutions put great emphasis on verifying the correctness of work, remote monitoring, shortening the time of service and possible repairs, anticipating the need to implement preventive actions to prevent failures and extensive analysis of the operation of the entire system.

- decentralised system architecture

- adjustable conveyor height

- enables service work limited to a single drive without shutting down the entire system

- providing a local and manual control system at the site of each drive

- simplifies diagnostics

- reduces installation and service time and cost

- significantly reduces the impact of the work on the operation of the entire system

- redundancy

- possibility of using redundant PLC controllers

- automated immediate switching operation between controllers allows for uninterrupted operation of the entire system even in the event of a PLC failure

- communication connections in the ring provide resistance to single faults or exclusions of a fragment of the network

- identification & measuring

- timeline visualization

- speed measurements of each transporter

- precise multi-head barcode readings with great efficiency and effectiveness

- video coding systems

- precise flow measurements of weight, dimensions and volume

- service & maintenance

- HMI (human – Machine Interface) allows easy access and diagnostic on each main cabinet

- extensive diagnostic allows for a thorough analysis of the system operation

- a mobile support system for service work with access to full documentation, operating instructions and spare parts inventory drastically reduces service time and allows you to avoid many errors caused by improper operation

- standardization of solutions in the entire system allows for easy maintenance of service efficiency