Devices and software portfolio

At Dimark, we produce all key mechanical components of our BHS systems in-house. In 2024, we launched a new production line built around three core principles: precision, efficiency, and sustainability.

Our Production Line

Our factory near Poznań is equipped with advanced CNC machines, robotic welding stations, and a fully automated powder coating system. Every part we build is tested for durability, safety, and long-term performance in real airport conditions.

This investment allows us to:

- shorten delivery times,

- improve quality control at every step

- reduce material waste

- and ensure full traceability of every component we ship

We designed the facility to minimize its environmental footprint. The powder coating process is emission-free, our smart energy systems optimize power usage in real time, and all production waste is recycled or reused whenever possible.

For our clients, this means access to airport-specific equipment that is:

- more reliable,

- easier to maintain,

- reduce material waste

- and ready for long-term use with minimal impact on the environment

Our production line is not just a factory. It is a key part of our commitment to real innovation and real impact.

Devices portfolio

Whether you're upgrading infrastructure or enhancing digital workflows, we’ve got you covered. Discover our purpose-built hardware seamlessly.

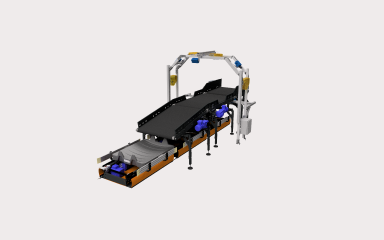

Belt line

Belt conveyor

Check-in

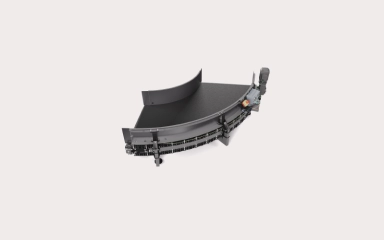

Curve conveyor

Merge conveyor

Induction conveyor

Common features

- Durable construction

- Low noise level and low energy consumption

- Easy maintenance and servicing

- Quick and effortless bełt replacement

- Adjustable height and speed

Shared benefits

- Accurate and rapid baggage sorting

- Reduced errors in baggage direction

- Seamless system expansion

- Shorter implementation time

- Increased operational reliability

Carousels line

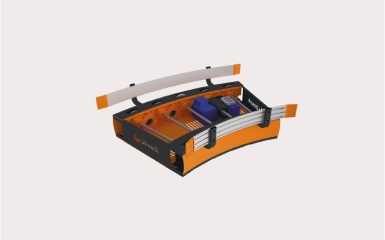

Flat carousel

Inclined carousel

Common features

- Durable construction

- Low noise level and low energy consumption

- Easy maintenance and servicing

- Quick and effortless bełt replacement

- Adjustable height and speed

Shared benefits

- Accurate and rapid baggage sorting

- Reduced errors in baggage direction

- Seamless system expansion

- Shorter implementation time

- Increased operational reliability

Sorting devices

Tilt-tray Sorter

Cross-belt sorter

Vertisorter

Horizontal diverter

Dual arm diverter

Common features

- Smooth baggage transfer and operation

- Adjustable conveyor height and speed

- Durable and robust construction

- Low noise level

- Easy maintenance and component replacement

- Modular and adaptable design

- High sorting rate

Shared benefits

- Accurate and rapid baggage sorting

- Reduced errors in baggage direction

- Seamless system expansion

- Shorter implementation time

- Increased operational reliability

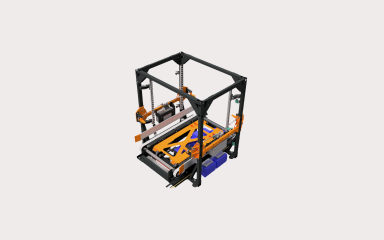

ICS line

Straight ICS

Curve ICS

Merge / Diverter ICS

Stacker

Top loader

Static discharge

Common features

- Individual baggage carriers

- Advanced control and visualization system

- Reduced energy consumption

- Higher sorting precision

Shared benefits

- Optimized operational costs

- Modular design

- High system reliability

- Enhanced baggage security

- Reduced environmental footprint

Automatic tray return system

Dilane

Common features

- Durable construction

- Low noise level and low energy consumption

- Easy maintenance and servicing

- Quick and effortless bełt replacement

- Adjustable height and speed

Shared benefits

- Accurate and rapid baggage sorting

- Reduced errors in baggage direction

- Seamless system expansion

- Shorter implementation time

- Increased operational reliability

Software Suite

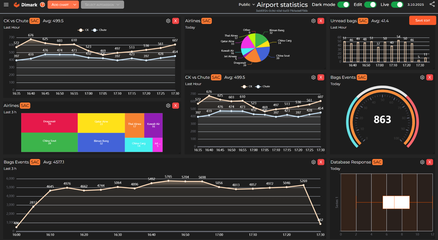

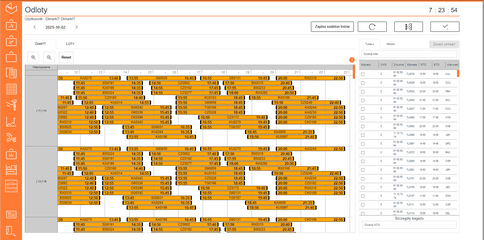

DiSCADA – Dimark Supervisory Control and Data Acquisition

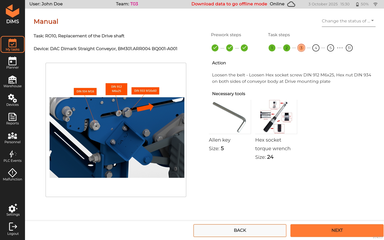

DiMS – Dimark Maintenance System

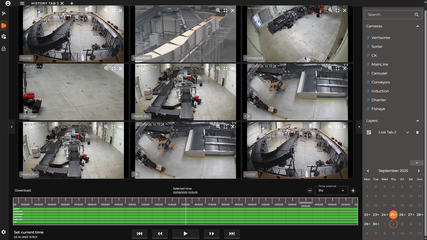

DiVMS – Dimark Video Monitoring System

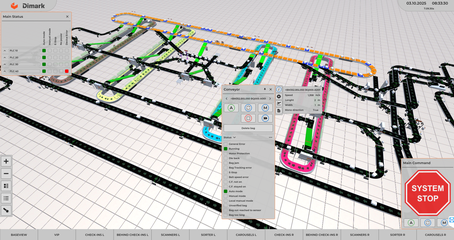

DiTwin – Dimark Digital Twin

DiControl – Dimark Automation Control Algorithms

DiSort – Dimark Sort Allocation Controler

Common features

- Unified software platform combining DiSCADA, DiMS, DiVMS, DiTwin, DiControl, and DiSort.

- Real-time control, monitoring, and diagnostics of the entire BHS.

- AI-driven insights for predictive maintenance and anomaly detection.

- Digital twin technology for simulation, testing, and safe deployment.

- Seamless integration with airport systems (AODB, DataBroker, etc.).

Shared benefits

- One interface for full system visibility and control.

- Reduced downtime and faster problem resolution.

- Smarter operations with data-driven decision making.

- Shorter project lead times and safer upgrades.

- Scalable, reliable solution proven in live airports.

From greenfield builds to live system upgrades, our solutions are tailored to your airport’s reality. Let’s talk about how we can help streamline, modernize, and future-proof your operations.